PROCESSES

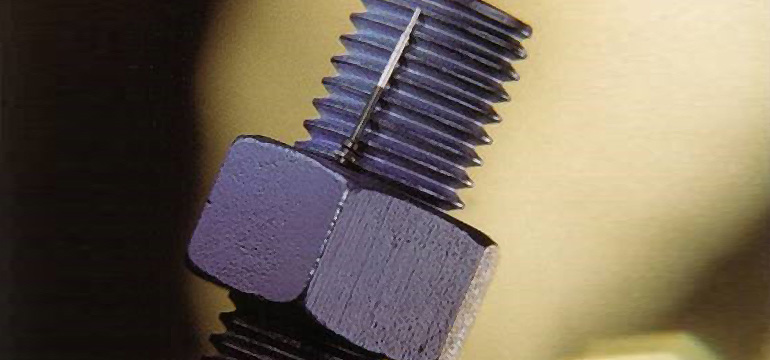

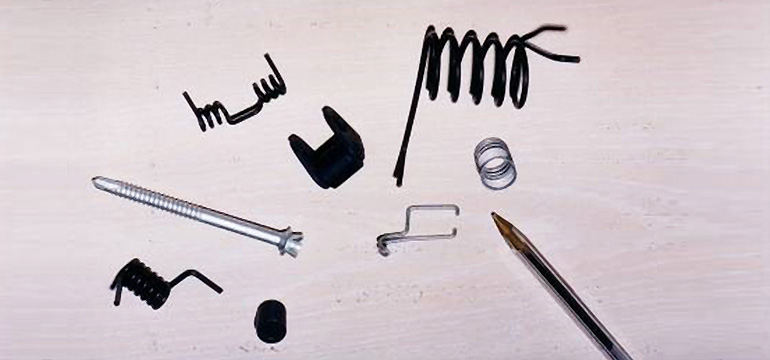

The surface treatment of a part consists in reinforcing and protecting it to enhance its basic properties and its adaptation to a certain environment. Surface preparation: Before treating parts on different substrates, their surface has to be cleaned in order to remove all impurities and to facilitate coating adhesion. To achieve this, there are several techniques available that we choose depending on our objectives: Degreasing and steaming the part in order to eliminate all grease or other residue, Pyrolisis, Sandblasting: micro-sandblasting to facilitate coating adhesion on the substrate, Masking: in order to avoid some areas (using a special tape,or a metallic/plastic assembly, or a special tool). We use diverse coating technologies depending on our customers’ needs.

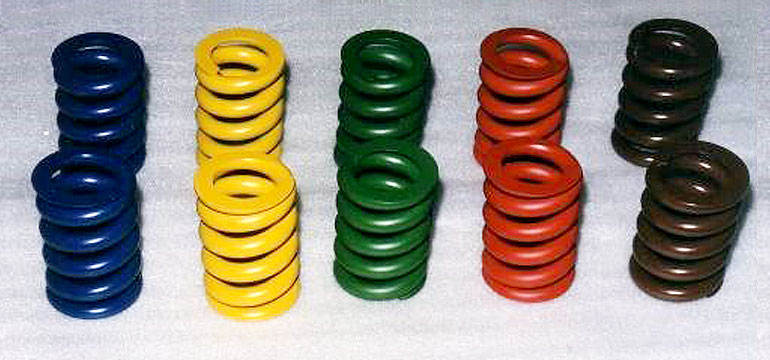

The surface treatment of a part consists in reinforcing and protecting it to enhance its basic properties and its adaptation to a certain environment. We have diverse coating methods: Liquid or electrostatic spraying, or fluidized bath : Fluorine-based (Teflon®), Implementation, before treatment, parts are: Degreased and steamed in order to eliminate any grease or residue, Micro-sandblasted in order to strip them and to facilitate coating adhesion, Spraying: Liquid spraying, electrostatic powder coating, fluidized bath, Embedding process: Implementation, before treatment, parts are : The part is micro-sandblasted in order to make it porous and to facilitate coating adhesion, Spraying : Using a process of cold spray, solid lubricant microparticles penetrate into the material to a depth of some microns and remain embedded in it forever, Microfral® 100 et 200 (graphite, MOS²).

We are able to provide the following processes: Liquid or pneumatic spraying (wet processing), Electrostatic powder coating, Fluidized bath, Dipping-centrifugation line, Embedding, Microfral® 100 et 200 (graphite, MOS²).

APPLICATIONS

OUR CUSTOMER REFERENCES

They trust us in France and internationally

AQUITAINE

9, Rue Vert Castel

Z.I. du Vert Castel

33700 MÉRIGNAC FRANCE

Téléphone : +33 5 56 15 05 00

Fax : +33 5 56 96 89 19

ILE DE FRANCE

2, Avenue du Président Salvador Allende

Z.I. Mozinor

93100 MONTREUIL FRANCE

Téléphone : +33 1 48 58 73 13

Fax : +33 1 48 58 81 85

fluorotechnique.fr • High performance polymer coatings applications • France

Legal Notice • Privacy Policy • General conditions of sale • General conditions of purchase

Copyright 2021 • TDR Designed by ARGONAUTT